DRTS Pipe Extruders

DRTS provides quality plastic pipe extruders for Single Screw and Twin Screw extrusion solutions, with a focus on quality and customer customization. We custom design our pipe extruder screws to fit your material combination ensuring homogeneous mixture, better plastification and production efficiency. Our pipe extruders are made with top European components such as Seimens, Zambello, ABB and other top brand components to ensure production stability, product quality and machine durability. Our extruders can be used to produce PE, PVC, PPR and drip irrigation pipe.

What Does a Plastic Pipe

Extruder Machine Do?

The pipe extruder machine, is the most important part of any pipe production line; it heats, mixes, and extrudes fesh pipe. A good extruder will ensure that you consistently produce quality pipe, allowing you to save money on scraped pipe and differentiate yourself from the competition.

Customized Single & Twin

Screw Extruder Machines

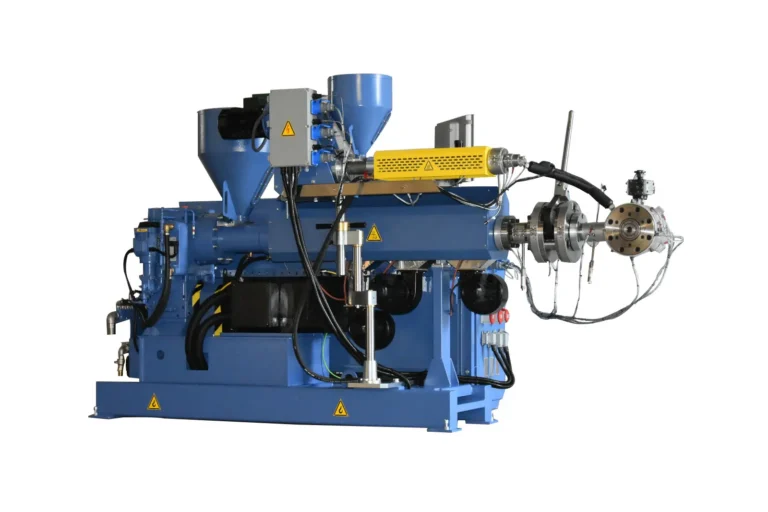

DRTS offers both single screw extruders for plain PE and drip irrigation pipe as well as twin screw extruders for PVC pipe production. Our plastic pipe extruders are custom built to your needs and constructed from industry leading, brand name components.

Why Do PVC Extruders Need

Twin Screws?

PVC extruders require twin screws to handle the extra wear and tear caused by the rough nature of raw PVC materials. Unfortunately, using PVC resin with a single screw extruder will cause accelerated damage to the extruder and inconsistent pipe production.

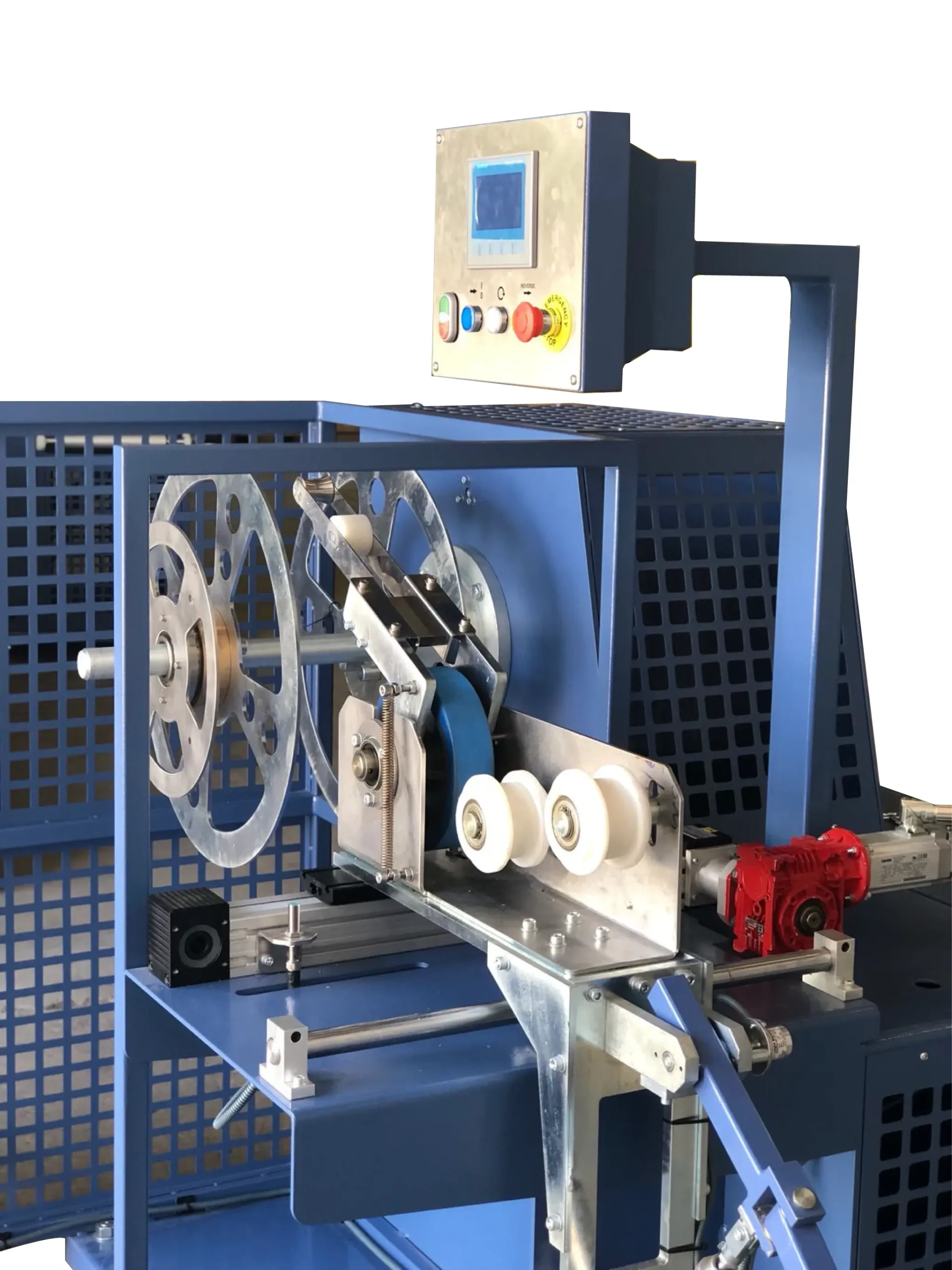

Extruder Machine

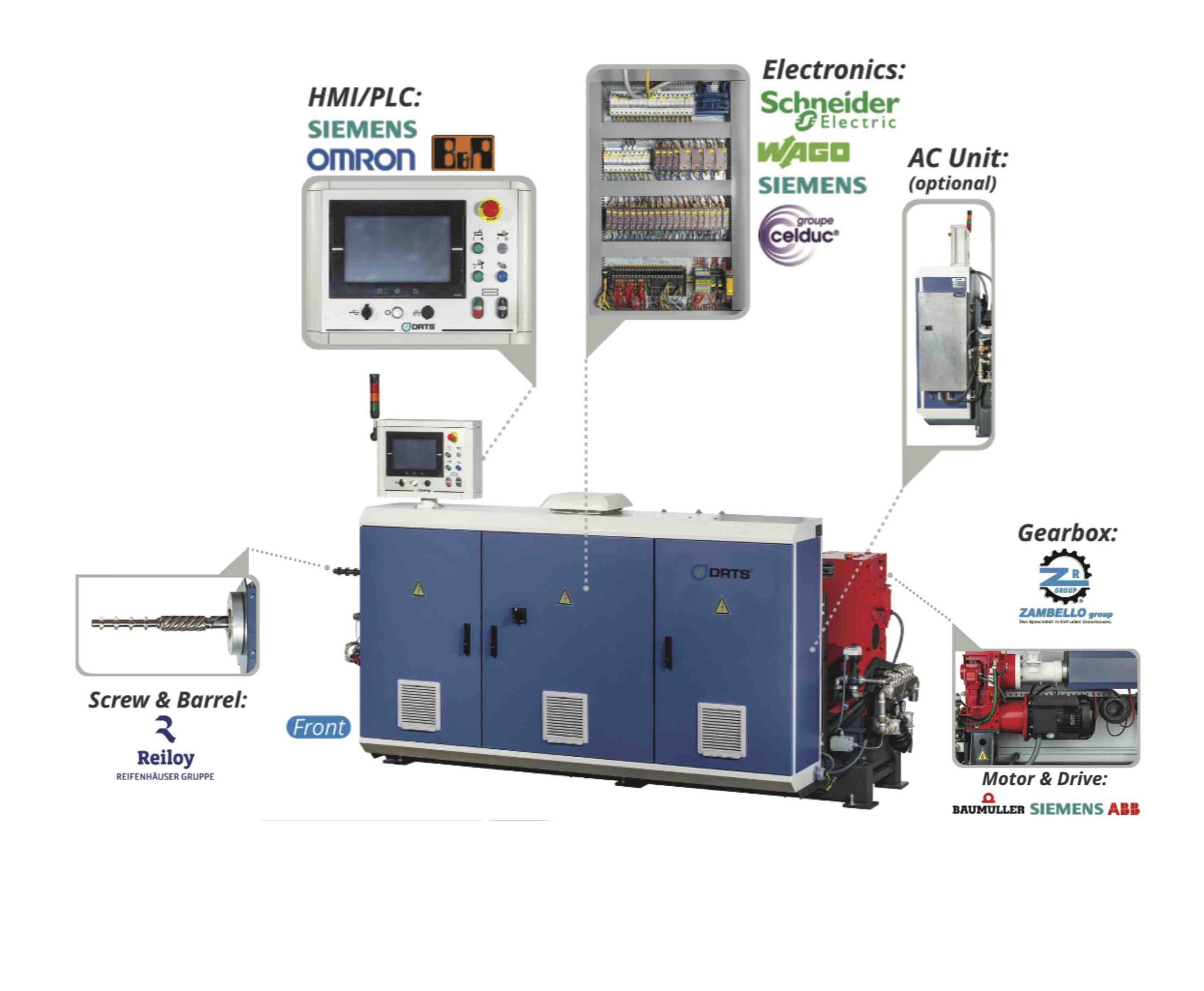

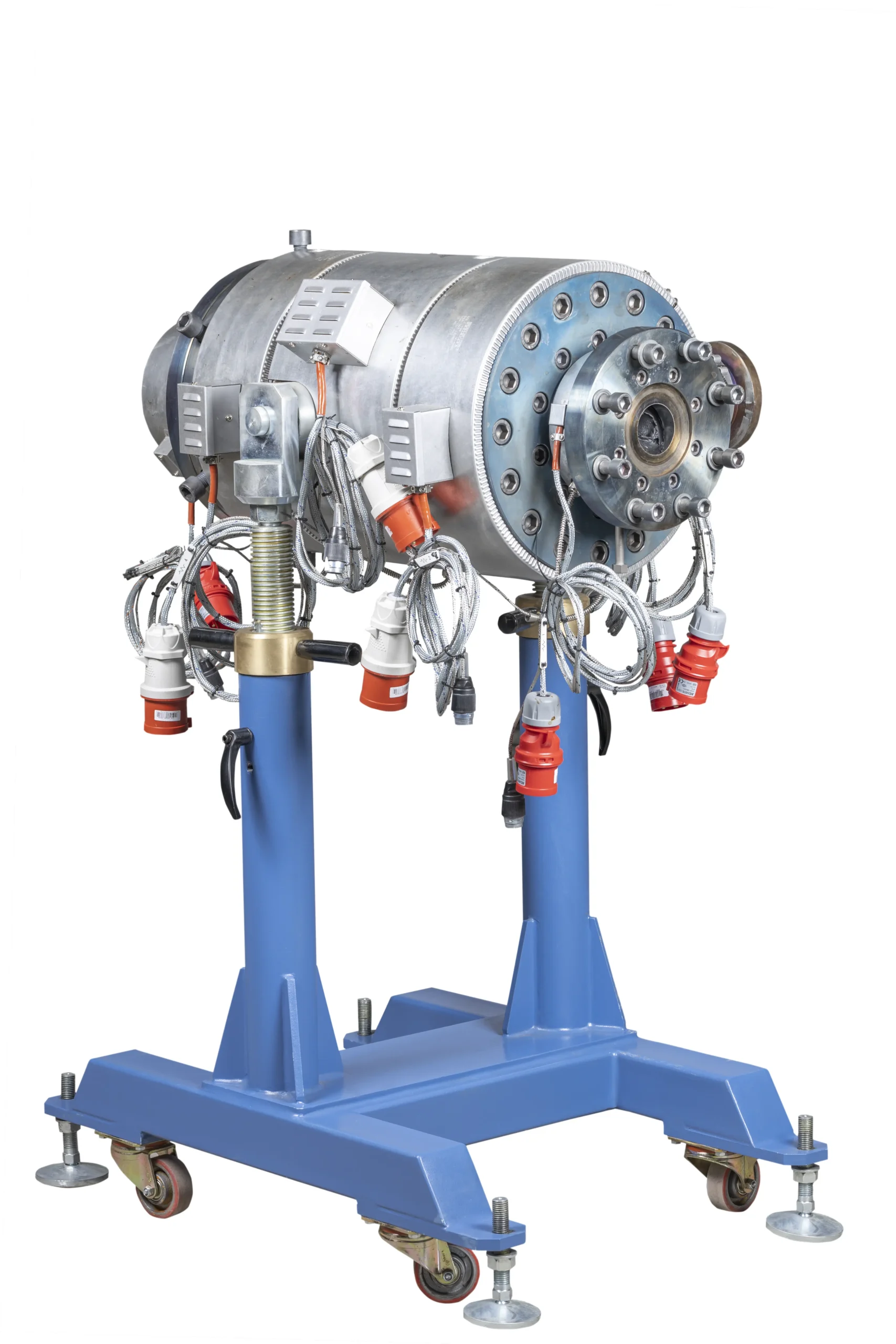

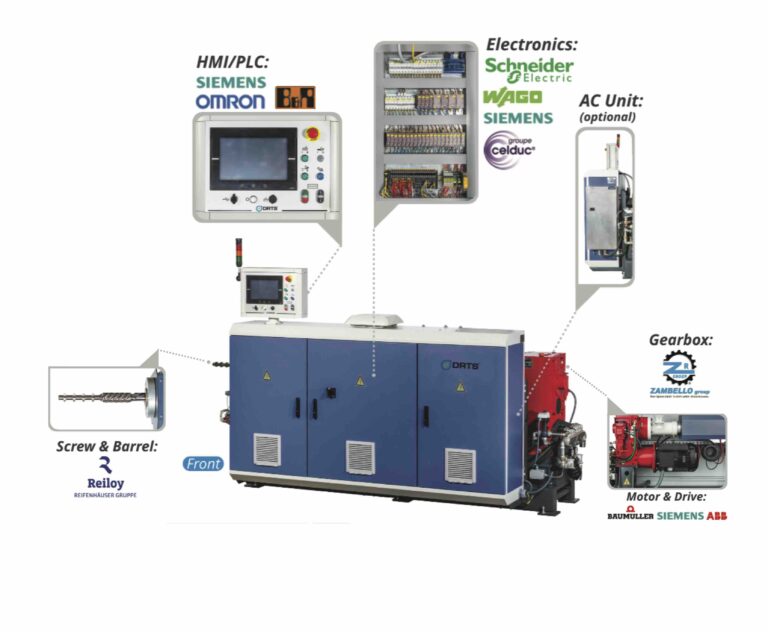

Our Extruder Machine Components

As an experienced pipe production line manufacturer for over 35 years, DRTS individually tested and approved global brands for the use of their components in our machinery. 95% of our extruder 3rd party components are European brands. This includes our Gearbox, Screw & Barrel, HMI control panel, Motors, Relays, Drives etc… Using these global brands not only assures our equipment’s quality and consistency but also allows our customers to receive service for these parts directly from the manufacturer who has a very widespread presence around the world. This creates a network of spare parts supply and technical assistance like no other.

Tying in all these brands into one state-of-the-art extruder is what makes DRTS equipment unique and so attractive.

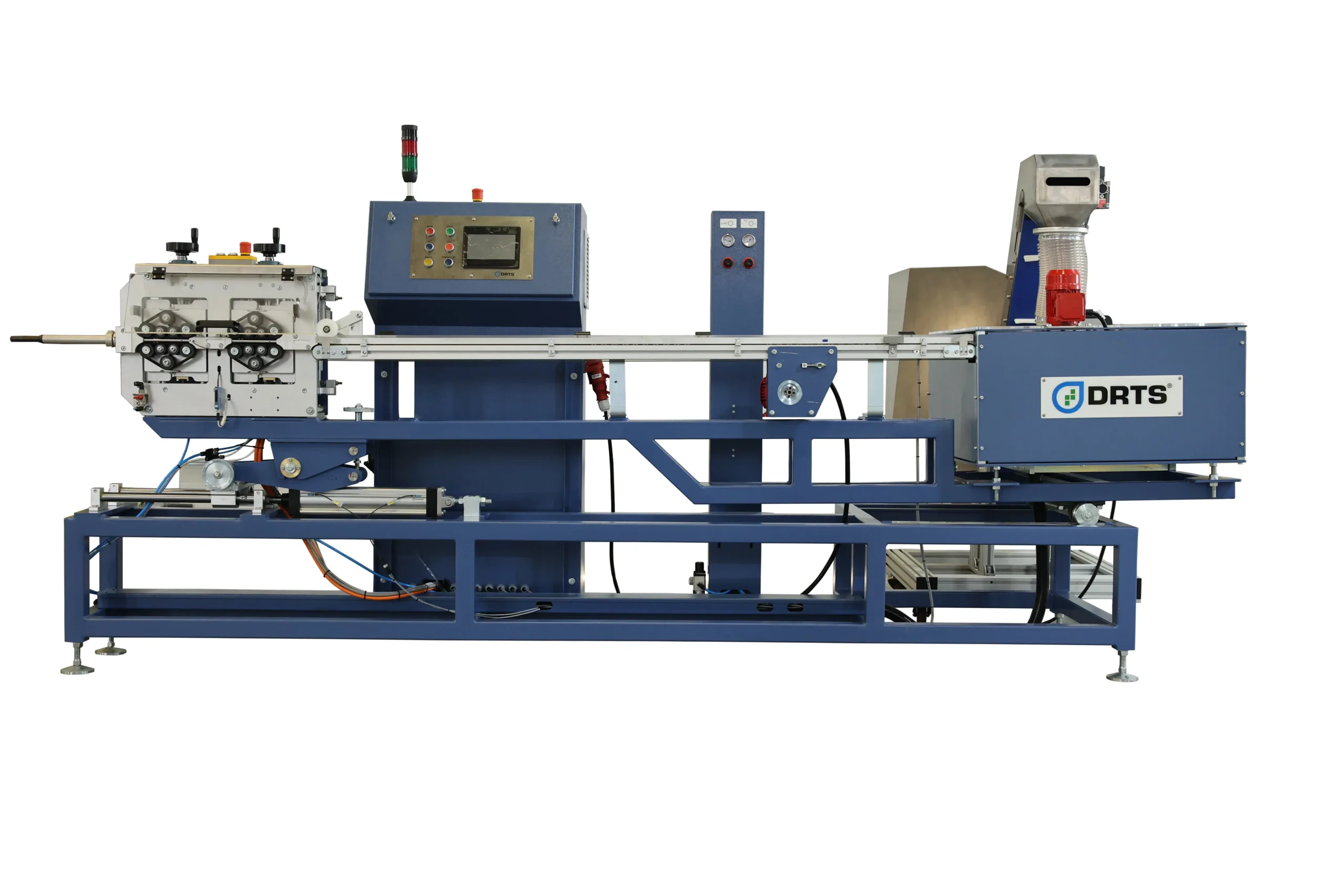

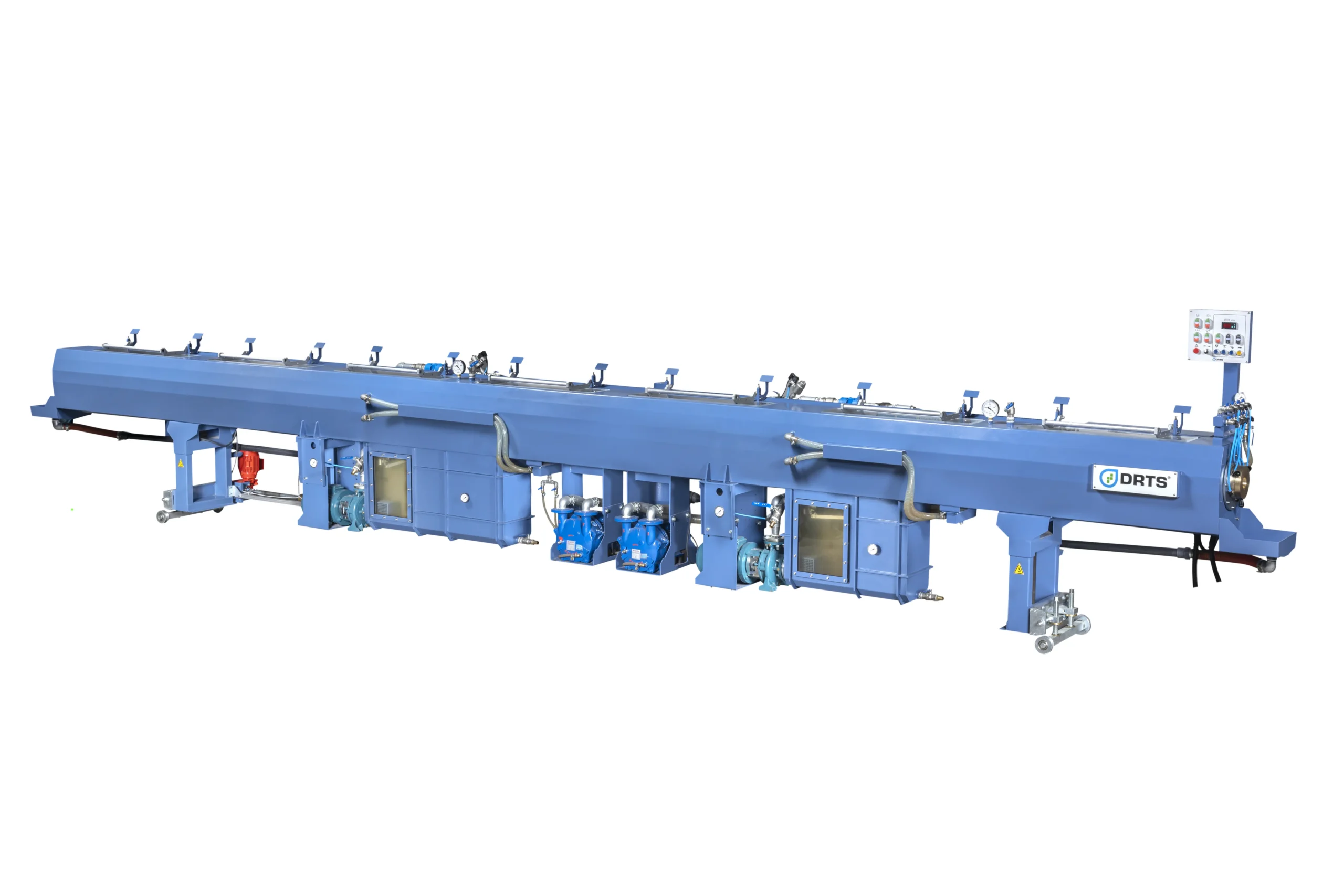

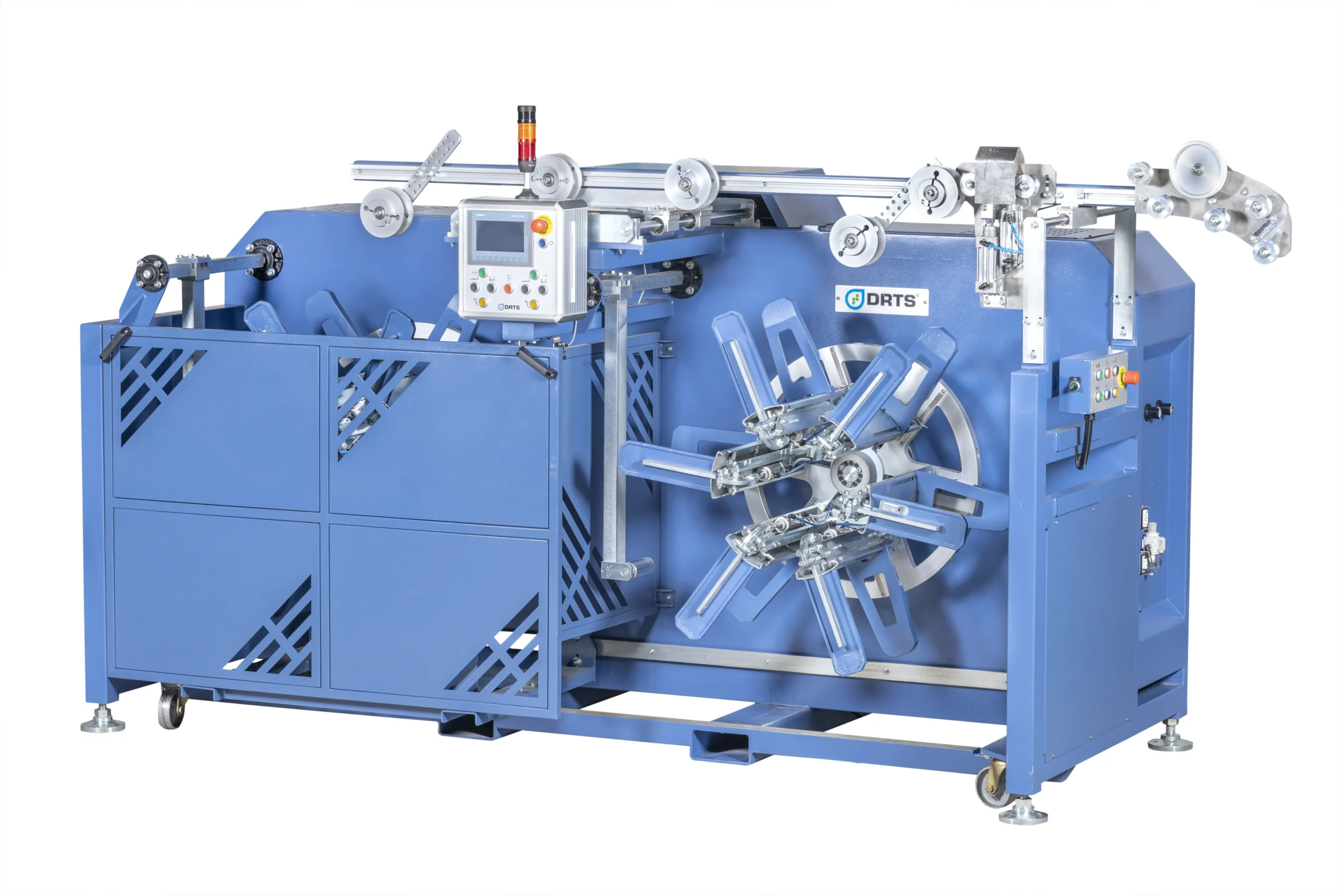

Our Turnkey Extrusion Pipe Machinery

Our turnkey HDPE extrusion machine boasts a range of production options. DRTS offers pipe production lines for pipes of 6mm-710mm (¼”-28”) diameter. We offer machinery to manufacture pipes of single layer, double layer and 3 layer pipes in many configurations. DRTS has the ability and experience to provide you HDPE extrusion machinery from what would be considered a basic line all the way to the most sophisticated production line. We integrate 3rd party machinery such as full gravimetric systems with line control, pipe measuring equipment, laser printers and much more.

The same is also offered for our PVC, PP and drip irrigation pipe production lines. Our flexible and customizable approach allows DRTS to fit a production line for almost every budget and every customer.

Plastic Extrusion Basic Working Concept:

Whether you are producing HDPE pipes, PVC Pipes, Drip irrigation pipes or any type of plastic pipe, the extrusion process is very much the same.

The Plastic material which can come in both pellet form or powder form (In the case of PVC) are fed into the extruder at room temperature. Feeding the material can be done manually or automatically by using gravimetric systems, vacuum feeders etc…

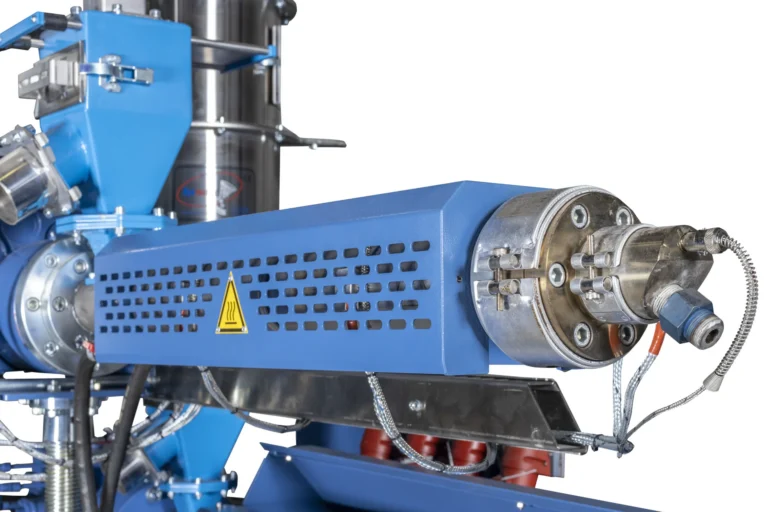

Once fed into the extruder throat, the heated Barrel melts the plastic material and changes it from a solid state to molten liquified plastics. The Screw inside the barrel rotates to create friction, mixing and generating further heat while pushing the material towards the Extruder’s tip. The extruder tip/flange is directly connected to the Die head or first goes through a screen changer. The die head is what makes the molten plastic form into the desired shape. This is where you set the tooling for the desired pipe size.

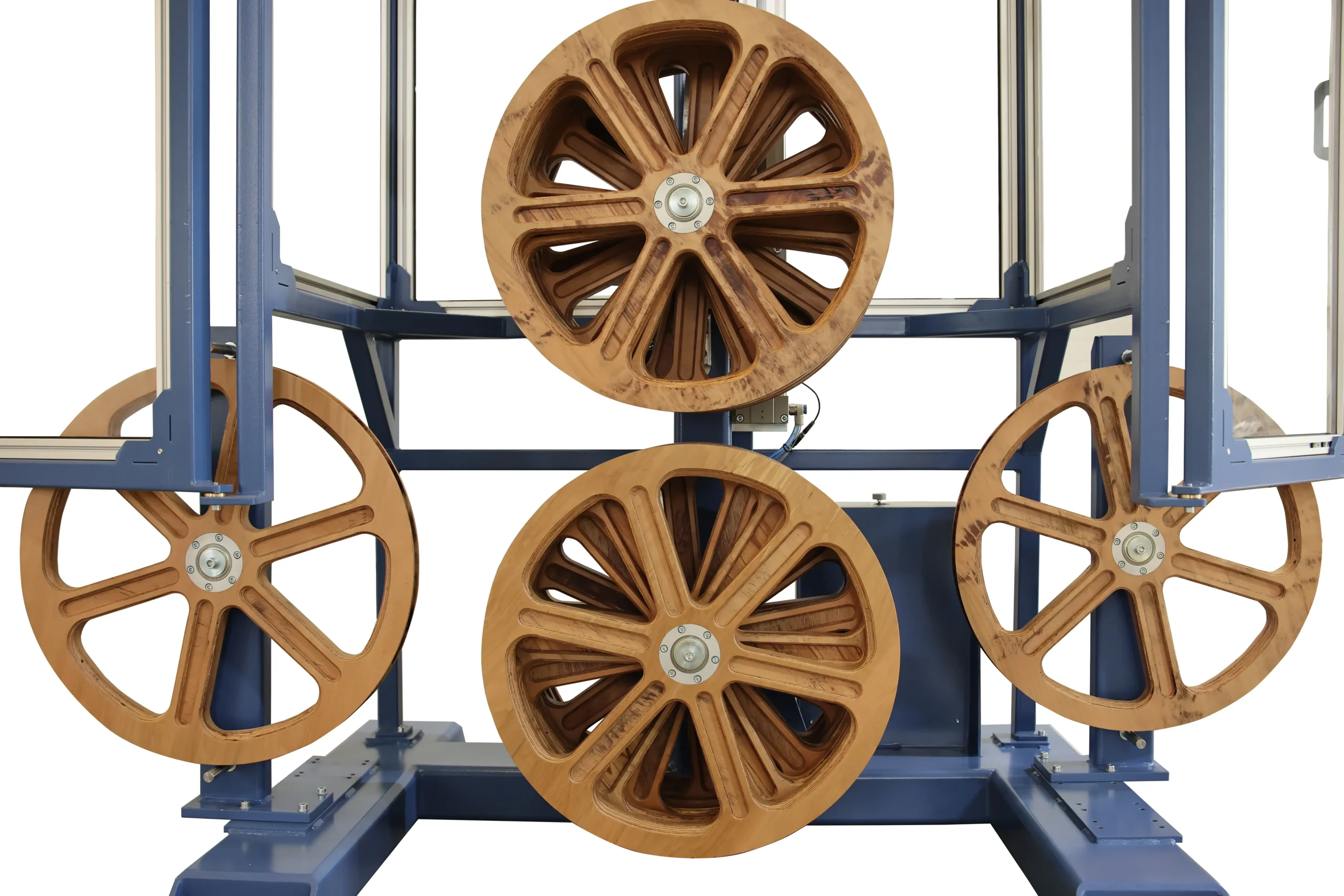

Further down beyond the die head is what is considered the downstream equipment which consists of a vacuum tank-to maintain the pipe shape, cooling tanks to further cool down the pipe and let it set and harden, Puller to pull the pipe, cutter- to cut the pipe to the desired length, Coiler- to coil the pipe or tipping table to collect the pipe in cases where its not coiled.

As an extruder machine manufacturer, DRTS uses high quality European components to ensure quality plastic pipe production and equipment longevity. Some key components of a plastic pipe extrusion line include the barrel, screws, motor, heater bands, and control panel. Our Reiloy barrel is where the raw materials are fed and heated to the desired temperature for extrusion. The screws inside the barrel rotate and push the molten plastic through the die to form the desired shape of the pipe. The motor provides the power to rotate the screws, while the heater bands maintain the temperature of the barrel. The control panel allows operators to adjust settings such as temperature, speed, and pressure to ensure optimal production. Overall, these components work together to create high-quality plastic pipes efficiently and effectively.

| Screw & Barrel: Bimetallic (Germany) or Nitreated DIN 1.8850 | Main Motor: ABB / Siemens / Baumuller | Driver: ABB / Siemens / Baumuller | HMI/PLC Control: 12” B&R/Siemens/Omron |

|---|---|---|---|

| PC Control: Optional 19” | Gearbox: Zambello – Italy | Heating Elements: Ceramic Heaters + Aluminium Separators | Melt-Pressure Sensor: Gerfan – Italy |

| Electric Components: Wago – ABB – Siemens – Schneider | Solid State Relays: Celduc / France | Air Condition: Optional |

Single Screw Extruders

Related Products

DRTS provides Single Screw and Twin Screw extrusion solutions with...

Contact Us Now

Our Location

Manas Bulvarı Adalet Mahallesi No:47 Kat:32

Phone Number

+1 (858) 412-0133 | +90 (232) 877 24 32

Email Address

info@drts-corp.com

"*" indicates required fields